Gain in-depth knowledge of laser processing

1.1 Factors affecting laser processing performance

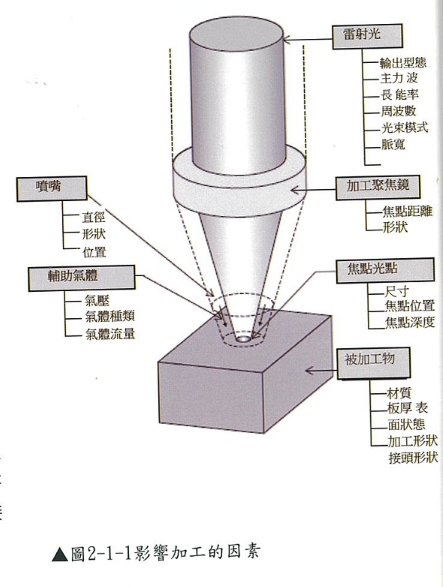

Laser processing, which uses laser light with high energy density focused on a tiny spot, can perform many processes that were difficult to perform using previous methods. The uses of laser processing include: cutting, opening holes, welding, heat treatment, etc. By properly controlling factors such as light energy density and auxiliary gas that affect the performance of each processing, the same processing machine can be used separately for various purposes. Figure 2-1-1 shows the factors that affect the processing performance when using a lens for laser processing.

(1) Factors related to laser light

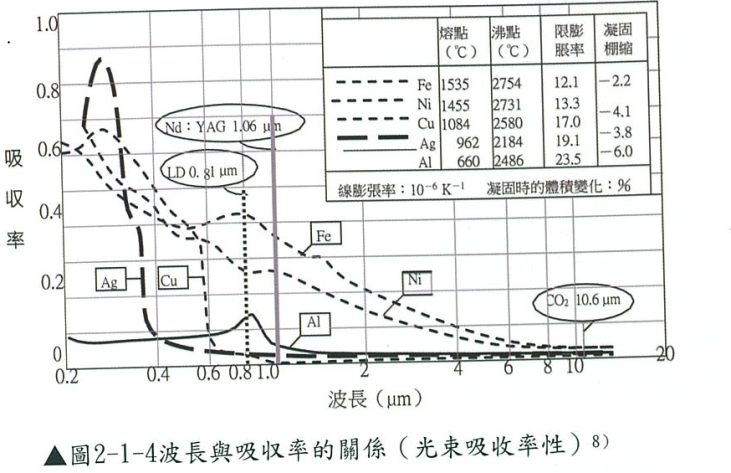

Output forms include CW oscillation of continuous laser output and pulse oscillation of repeated on and off. The wavelength determined by the laser oscillation medium affects the beam absorption characteristics of the object to be processed. Output indicates the amount of light energy, energy rate indicates the ratio of the light speed on time per pulse time in pulse output, frequency indicates the number of oscillations per second, and beam mode indicates the intensity distribution of light energy. In addition, shortening the pulse width time allows non-thermal processing.

(2) Factors related to lens processing

The focal distance refers to the distance from the lens position to the focal position, and affects the spot diameter and focal depth at the focal position. Processed lens types include concave-convex lenses that suppress aberrations and general plano-convex lenses.

(3) Factors related to laser light

The spot diameter depends on the lens specifications. The shorter the lens focal point, the smaller the spot diameter. The focal position indicates the relative position of the focal spot to the surface of the workpiece, and defines the upper side as a positive value and the lower side as a negative value. The focal depth indicates the range obtained by the diameter close to the spot diameter near the focal point.

(4) Factors related to the nozzle

The nozzle diameter affects the evaporation and melting state of the workpiece and the shielding of the processed part. In order to make the processing performance in all directions uniform, the front end of the nozzle is round, and the position relationship between the nozzle and the surface of the workpiece must be kept constant at all times and as narrow as possible.

(5) Factors related to auxiliary gas

The auxiliary gas pressure affects the discharge of the metal melted by the laser light from the cutting groove. The type of gas affects the processing quality and processing capacity. Cutting relies on the combustion of oxygen, and welding and heat treatment require shielding of the processing part. The optimal gas flow rate is maintained according to the nozzle used.

(6) Factors of the workpiece include:

The material and thickness of the plate affect the light energy consumption, and the processing shape is easily affected by the surface state and heat concentration used to stabilize the light beam absorption. In addition, the shape of the material joint must also be considered for welding.

1.2 Main types of lasers used in processing

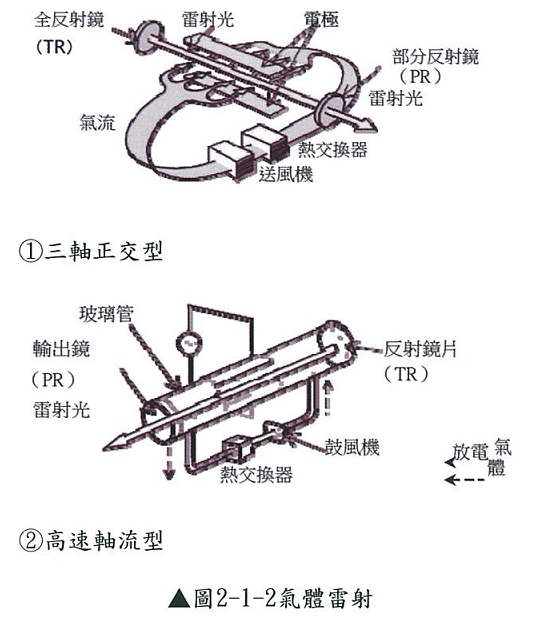

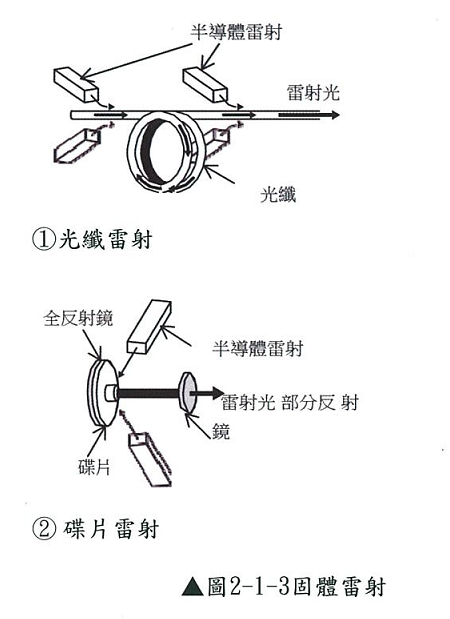

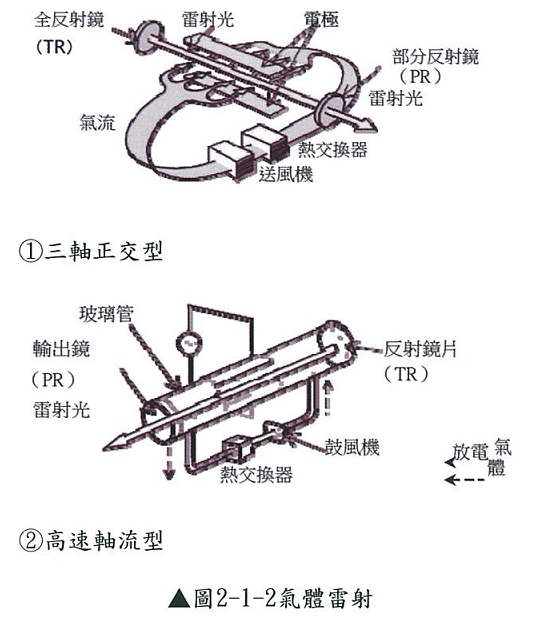

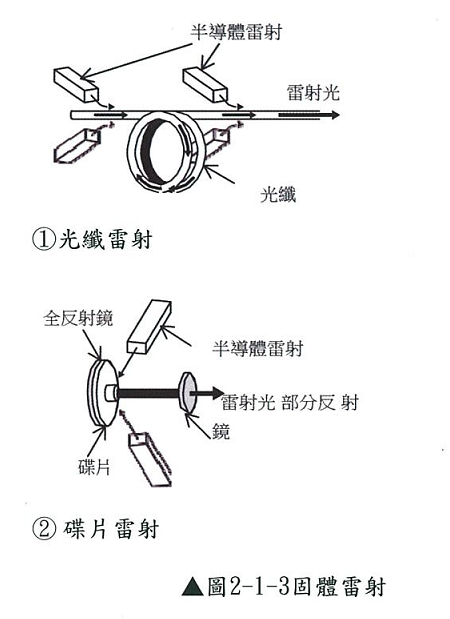

High-output lasers for processing are generally divided into gas lasers and solid lasers. Gas lasers used for sheet metal processing used to use carbon dioxide lasers, as shown in Figure 2-1-2. Depending on the discharge direction, laser gas flow direction, and laser light emission direction, they include ① three-axis orthogonal type and ② high-speed axial flow type. Although the oscillator structures are different, the laser generation principle is to use a mixed gas containing carbon dioxide as a laser medium (laser light generation source) and use discharge to generate lasers. The laser light emitted from the laser oscillator is reflected by several mirrors and propagated to the processing head. Solid lasers used to use semiconductor lasers (or lamps) to laser a glassy crystal (solid) called YAG (short for yttrium aluminum garnet). However, when using continuous high output, thermal deformation called the heat lens effect occurs in the YAG rod, which deteriorates the quality of the laser light. Therefore, in order to reduce the heat lens effect, ① fiber lasers using optical fibers as the laser medium and ② disk lasers using flat (disc-shaped) crystals as the laser medium have been developed. These laser lights are transmitted to the processing head via the optical fiber. In addition, high-output semiconductor lasers can also be used to directly process resins or metals. However, when the processing object of semiconductor lasers is metal materials, it is not suitable for cutting due to insufficient focusing, so the scope of use is limited to applications such as heat treatment and welding.

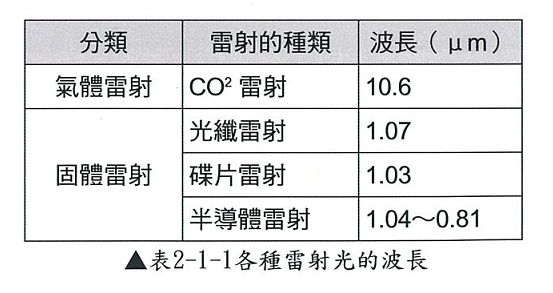

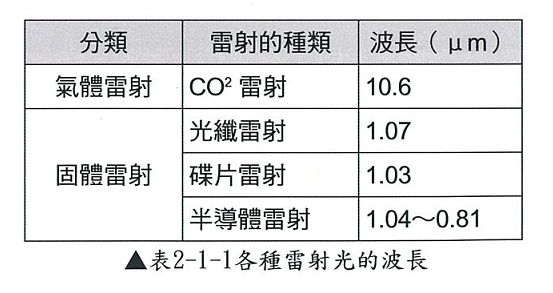

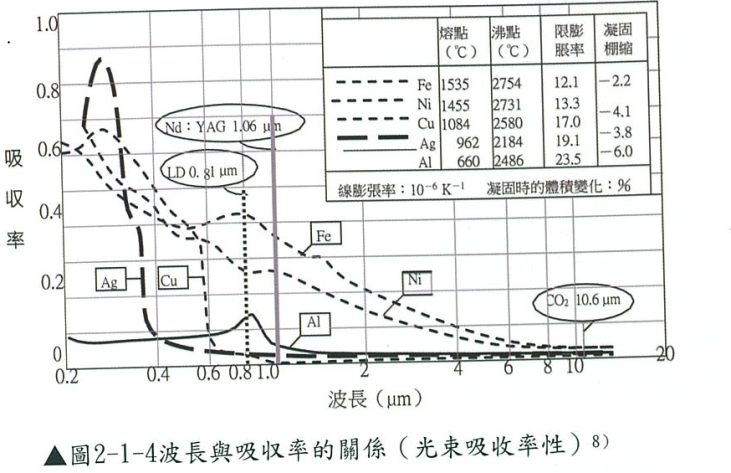

Table 2-1-1 shows the wavelengths of various laser beams. The laser beam focused by the processing lens can basically be concentrated into a smaller spot diameter as its wavelength is shorter. The smaller the spot diameter, the higher the light energy density, so the ability to melt metal is strong and high-speed processing is possible. In addition, the wavelength also affects the beam absorption characteristics of the object being processed. Figure 2-1-4 shows the wavelength of laser light and the absorption wavelength band of various materials. The shorter the wavelength, the higher the absorption rate of various materials. The absorption rate of high-power output semiconductor lasers for aluminum is twice that of fiber lasers and 10 times that of carbon dioxide lasers, and is widely used in heat treatment and welding applications. However, the biggest problem with semiconductor lasers is the low focusing characteristics mentioned above, so it is expected that research to improve the focusing characteristics will help expand applications in the cutting field.Laser cutting costs How should customized products be priced? The price of laser cutting sheet metal

1.3 Main types of lasers used in processing

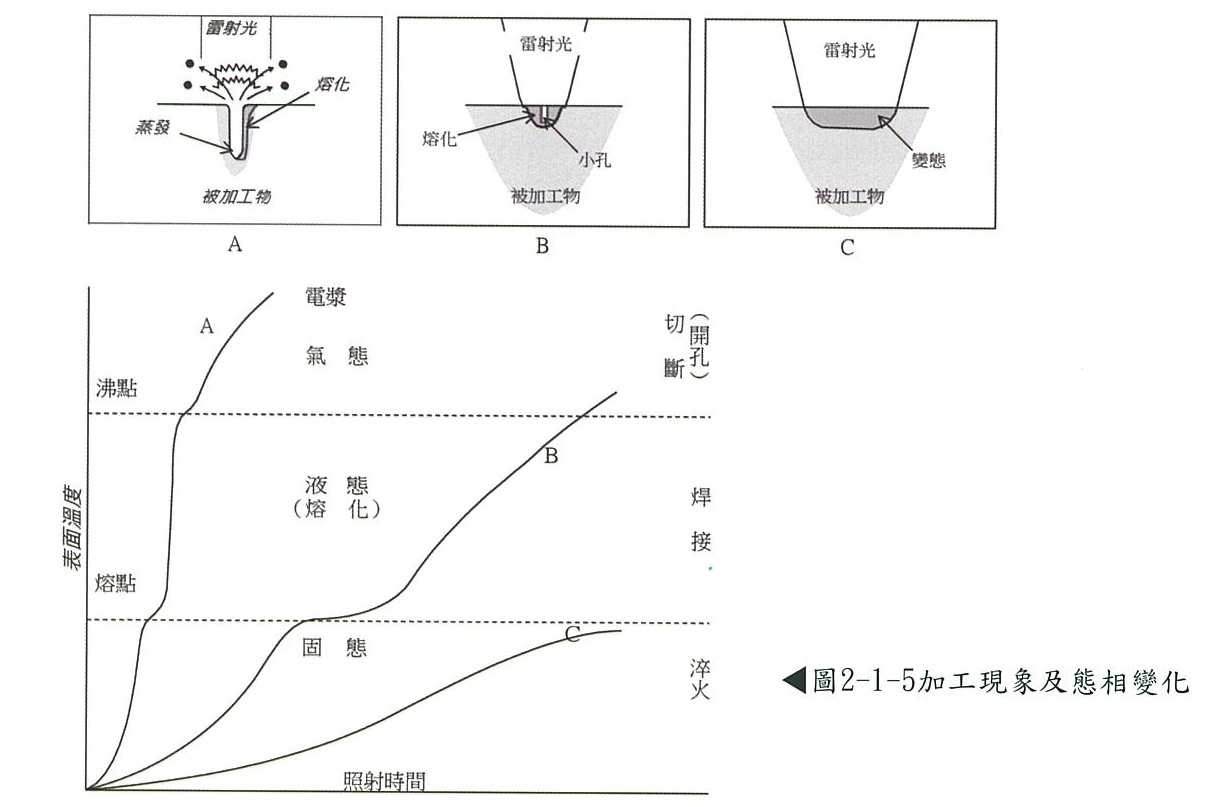

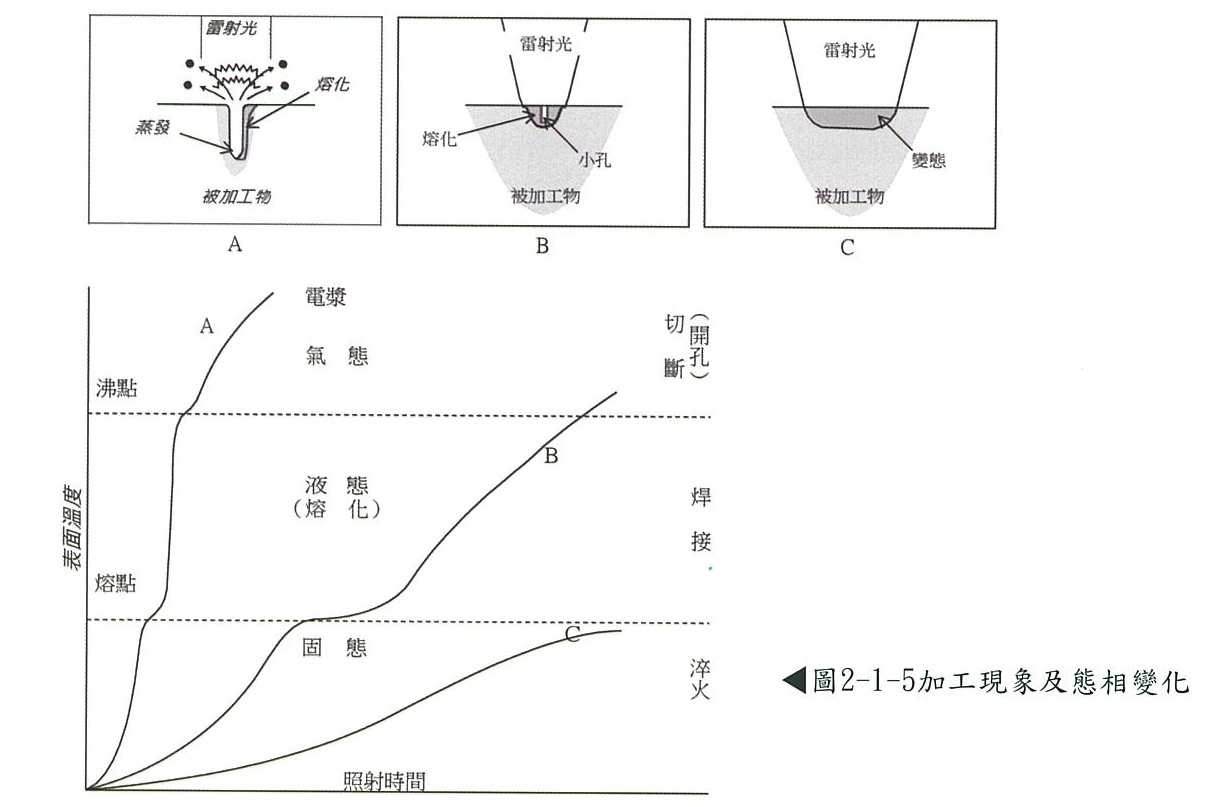

Different processing is performed according to the light energy density and exposure time of the laser light irradiated on the workpiece and the effect of the auxiliary gas.

Figure 2-1-5 conceptually shows the difference in processing phenomena of cutting, welding, and quenching based on the relationship between the exposure time of the laser light and the temperature change of the workpiece. Metal materials are solid at low temperatures, become liquid when they reach the melting point, and become gas when they reach the boiling point. Laser processing is to perform various processing by optimally controlling the time of the three-state change and the rising temperature according to the processing purpose.

When the light density of the laser beam is increased, the metal state changes from solid to liquid and gas in a short time as shown by line A in the figure. As a result, it is possible to perform opening or cutting processing with little thermal impact on the surrounding area.

In the case of line B in the figure, it takes time to reach the gas state with a lower light energy density than line A, but most of it remains in the liquid state. Welding is performed by this change. Laser welding is to form a small hole under the processing head with high light energy density, and fill the molten metal generated around it into the small hole for welding.

Copper welding manufacturer

welding on behalf of customers

The situation of line C in the figure is that it takes time for the surface temperature to rise further, and the temperature rise stops in the solid state and quenching is performed.

By utilizing this feature that allows easy control of the laser light energy density and exposure time, the following laser processing is achieved.

- Hard and brittle samples such as ceramics, glass (quartz, etc.), bricks, and artificial marble can be easily processed.

- Because it is a non-contact processing, there is no reaction during processing. Materials such as plastics, cloth, rubber, paper, and extremely thin objects will not be deformed, and high-precision processing is possible.

- When combined with an NC control device, processing can be performed by programs that create arcs, straight lines, or free curves. Cutting and grinding can process complex and fine shapes that are difficult to process.

- Because it is a non-contact processing 211, the noise generated during processing is very small, and no matter what the processing machine is set up in, it can run continuously at night.

- By controlling the energy density and intensity distribution of laser light, cutting, welding and heat treatment can be performed.

- Since CO2 lasers can be transmitted to distant places at a small diffusion angle in the atmosphere, and fiber lasers can be transmitted using optical fibers, the processing range is expanded and time-sharing processing is possible.

- Since the focal spot diameter of the beam is small, local processing can be performed, so processing with small processing deformation and thermal deformation can be performed.

- Laser light splitting technology can be efficiently processed using optical components such as semi-reflective mirrors and holograms.

- Compared with electron beam processing, it is easier to establish a processing system because it does not require vacuum, does not generate X-rays, and is not affected by magnetic fields.

- Since fiber lasers can transmit laser light via optical fibers, it is easy to build processing systems with complex beam propagation paths that can be combined with robots, etc.

Laser processing service consultation(02)2290-1316。

Metal laser cutting Taipei