What is laser processing technology?

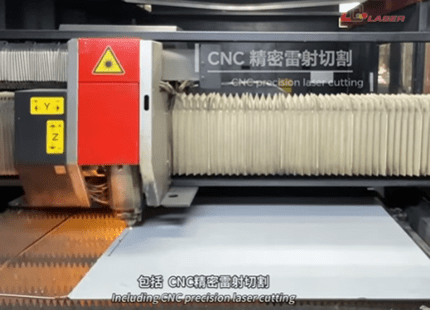

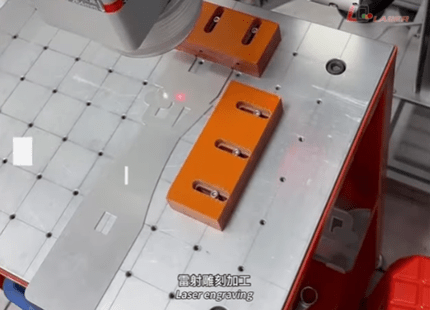

Laser machining is a process that uses high-energy laser beams to cut, engrave and mark materials. Laser machining is a widely used manufacturing technology in different industries. It is mainly used for high-precision cutting, engraving, punching and marking of various materials.

Laser processing is an indispensable technology in modern manufacturing and design. They provide highly precise, flexible and reliable manufacturing solutions for a wide range of applications. We have become a trusted partner for our customers with our fast delivery and customized order services. We not only provide high efficiency and flexibility, but also ensure that each order meets the highest standards.